Ensuring optimal indoor air quality (IAQ) in the workplace is essential for employee health, productivity, and compliance with UK regulations. Effective workplace air quality monitoring involves assessing the presence of hazardous substances, implementing control measures, and maintaining air quality within legal limits.

Monitoring workplace air quality is vital to protect employee health, enhance productivity, and ensure regulatory compliance. Here are some reasons why you should invest in workplace air quality monitoring:

Exposure to airborne contaminants like dust, fumes, and vapors can lead to respiratory issues and other health problems.

Good air quality contributes to employee comfort and efficiency.

Adhering to standards set by the Health and Safety Executive (HSE) and regulations such as the Control of Substances Hazardous to Health (COSHH) is mandatory.

In the UK, the Workplace (Health, Safety and Welfare) Regulations 1992 require sufficient ventilation in workplaces. Additionally, COSHH Regulation 10 mandates employers to monitor exposure to hazardous substances when a risk assessment indicates potential exposure.

To maintain optimal indoor air quality in the workplace, consider the following best practices:

Maintain ventilation systems to provide a consistent supply of fresh or purified air.

Deploy continuous IAQ monitors to detect pollutants in real-time, enabling prompt corrective actions.

Inform staff about the importance of IAQ and encourage practices that support a healthy indoor environment.

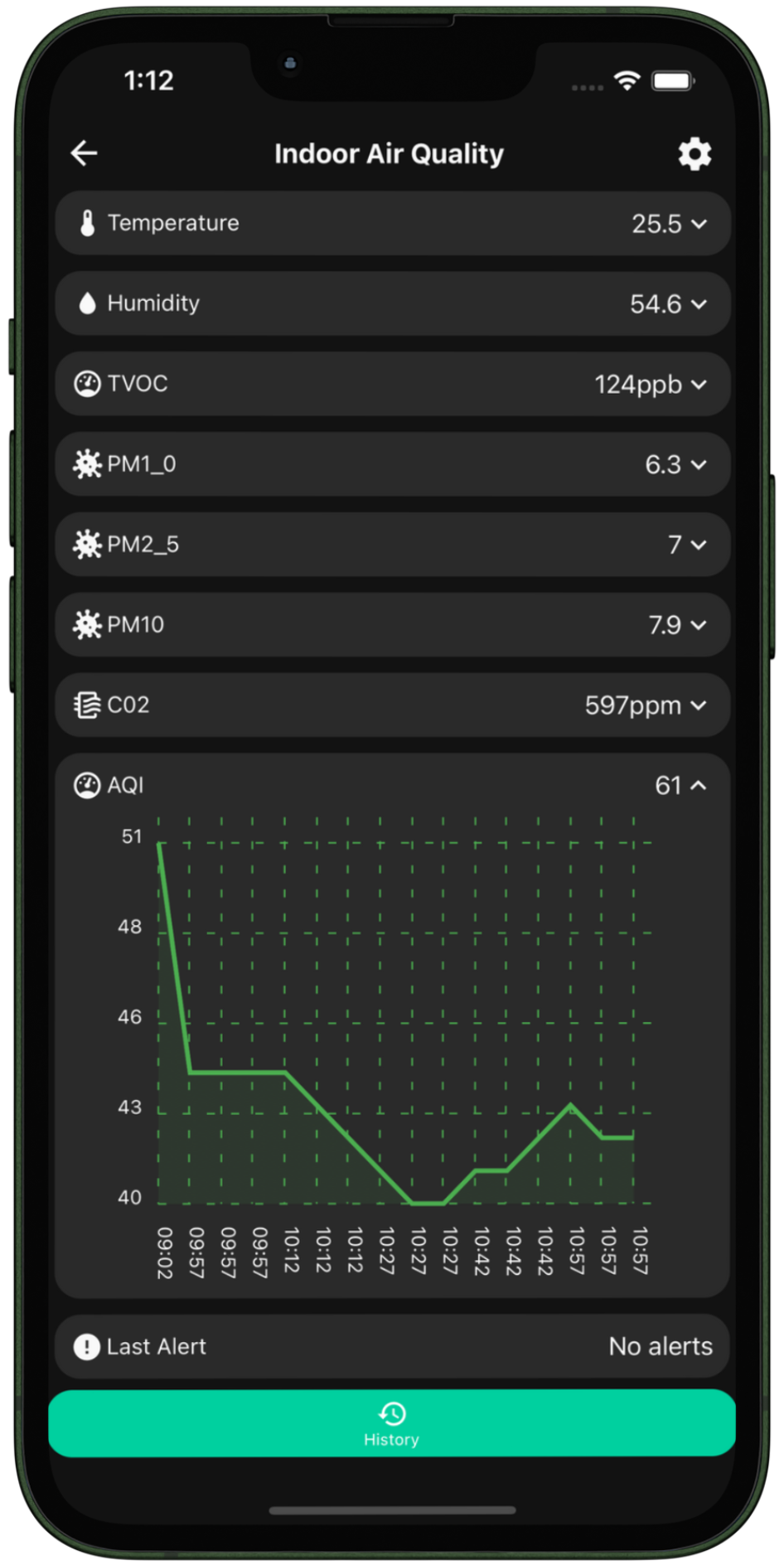

Trackpac offers a range of sensors and devices to help you monitor workplace air quality effectively. Our solutions provide real-time data on indoor air quality parameters such as temperature, humidity, CO2, and VOCs. With Trackpac, you can create a safe and healthy work environment for your employees.

Compact IP65-rated LoRaWAN temperature and humidity sensor with up to 10 years of battery life for environmental monitoring

Find Out More

IP65-rated LoRaWAN temperature and humidity sensor with up to 10 years of battery life for indoor and outdoor environmental monitoring

Find Out More

LoRaWAN indoor air quality sensor for monitoring temperature, humidity, and CO2 levels with LED indicator and long battery life

Find Out More

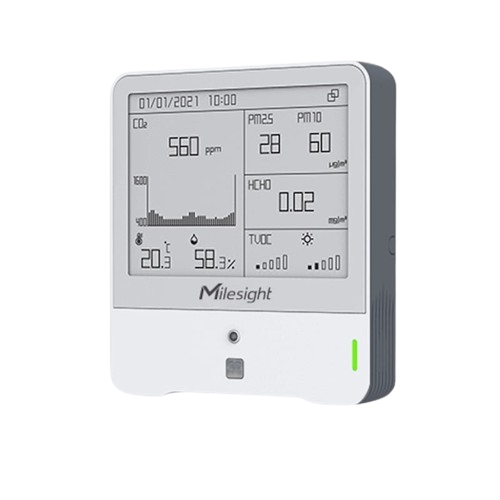

Air Quality Sensor for Indoor Air Quality with Temperature, Humidity, C02, TVOC, PM2.5, PM10

Find Out MoreInterested in a demo of how our workplace air quality monitoring solutions can help you create a safe and healthy work environment? Let's meet!

30 minutesNo commitmentPick any time

FAQ

Everything you need to know about Trackpac's IoT sensor management platform

Air quality in the workplace can be monitored using various methods, including personal air sampling, area monitoring, and the use of air quality sensors and detectors.

Yes, air quality monitoring is a legal requirement in many countries, including the UK. Employers are required to monitor air quality to ensure a safe and healthy working environment for employees.

The frequency of workplace air monitoring depends on the nature of the workplace, the type of contaminants present, and the level of risk. High-risk environments may require more frequent monitoring.

Air quality monitoring is made easy with Trackpac, add your sensors and get live metrics around air quality in your workplace.

Workplace air quality monitoring involves assessing the levels of airborne contaminants, such as dust, fumes, gases, and vapors, to ensure a safe and healthy working environment for employees.

Poor air quality can lead to health issues, reduced productivity, and non-compliance with regulatory standards. Monitoring ensures a safe environment and compliance with legal obligations.

Common sources include industrial processes, use of hazardous chemicals, poor ventilation, construction dust, and emissions from equipment or machinery.

The key regulations include the Workplace (Health, Safety and Welfare) Regulations 1992, the Control of Substances Hazardous to Health (COSHH) Regulations, and HSE’s Workplace Exposure Limits (WELs).

The frequency depends on the nature of the workplace, processes involved, and the risk of exposure. High-risk environments may require continuous or regular periodic monitoring.

WELs are the maximum concentrations of hazardous substances in the air, defined by the Health and Safety Executive (HSE), that workers can be exposed to without adverse health effects.

Common methods include personal air sampling, area monitoring, and biological monitoring to measure contaminants in the workplace.

Devices like gas detectors, particulate monitors, and IAQ sensors are commonly used to measure pollutants in the workplace.

Poor air quality can cause respiratory issues, headaches, fatigue, allergic reactions, and long-term illnesses like asthma or chronic obstructive pulmonary disease (COPD).

Employers can install and maintain ventilation systems, regularly monitor air quality, educate employees on safe practices, and reduce the use of hazardous substances where possible.

Still have questions?

Contact our support team